Our visual testing service offers a thorough evaluation of your product's surface condition, providing you with an accurate assessment of its quality. Our skilled technicians utilize the right techniques and equipment to detect visual defects and anomalies such as cracks or corrosion. This verifies the integrity of your products.

X-ray radiography is a powerful tool for non-destructive testing, allowing us to inspect the internal structure of materials and components without causing any damage. We use advanced equipment to produce high-resolution images that can detect even the smallest defects, such as cracks, porosity, and inclusions. Our experts are trained to interpret these images and provide accurate and reliable results. We also provide equipment maintenance to ensure its proper functioning. In addition to providing accurate and reliable results, the security of the X-ray equipment and the protection of the operators and the environment are also a top priority. To ensure this, we follow strict guidelines and protocols, such as limiting access to the X-ray equipment to authorized personnel, using shielding to minimize exposure to ionizing radiation, and regularly monitoring the equipment for any signs of malfunction or damage.

Using gamma rays, we can create detailed images of the internal structure of heavy components, such as pipes, tanks, and pressure vessels. This method is ideal for inspecting large, thick components that cannot be examined with X-ray radiography. Our engineers are trained to interpret these images and provide precise and consistent data.

Magnetic Particle Inspection is a testing method that we offer to detect surface and subsurface discontinuities in ferromagnetic materials. We use a magnetic field to induce a current in the material being inspected, and then apply a magnetic particle medium to the surface. Any defects will be indicated by the accumulation of magnetic particles. With our service, you will receive accurate results on time from our skilled technicians.

Dye Penetrant Testing is a non-destructive testing technique that we use to identify surface flaws in multiple non-porous materials. The process is relatively simple, yet highly effective at identifying defects that may not be visible to the naked eye. It involves coating the material with a liquid solution, allowing it to permeate into any cracks or defects present, then wiping away any excess and applying a developer to the surface. The developer acts as a magnet for the penetrant that has seeped into the cracks or defects, drawing it out and making the defects visible.

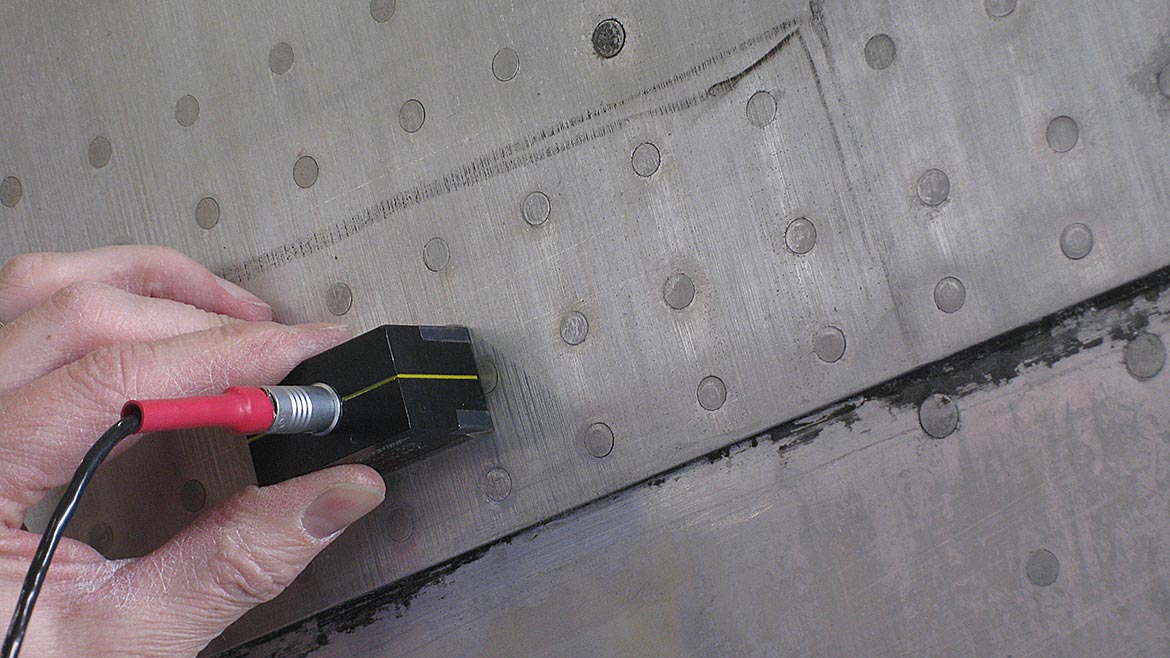

At our company, we utilize advanced equipment to identify faults and imperfections in materials and components. Our inspection process involves the use of high-frequency sound waves, which allow us to thoroughly examine metal components, welds, and other materials for laps, lack of fusion, and bonding issues. Our team of specialists is highly trained in this method, ensuring that all materials and components meet the required specifications. By using this advanced equipment, we are able to maintain the highest standards for quality control and assurance.

Our Positive Material Identification service uses non-destructive X-ray fluorescence technology to accurately determine the chemical composition of metal alloys. Our team of certified technicians is equipped with advanced XRF analyzers to provide fast and reliable results. PMI testing is crucial for verifying the authenticity and compliance of your materials. That is why we scrutinize your alloy to ensure that it meets the industry specifications, guaranteeing the quality and safety of your products. Contact us to schedule PMI testing for your materials.

One of our most reliable methods that we use is Eddy Current (ET), which involves inducing a magnetic field in a metal object and measuring changes in the flow of the magnetic field. This allows us to detect a wide range of defects, including laps, deformation, and seams. Our technicians use state-of-the-art equipment to provide accurate and efficient results in real-time. ET is versatile and we can apply it to various materials, such as aluminum, brass, and steel.

We use advanced equipment to accurately detect and analyze any changes in the acoustic waves produced by a material under stress. This allows us to identify any possible defects. Our AE inspection process involves applying sensors to the material's surface and monitoring the acoustic signals emitted during the testing process. Based on the analysis of the signals, our technicians provide a detailed report of the findings and recommendations for repairs. AE is a fast and efficient method for ensuring the safety and reliability of industrial components and structures.

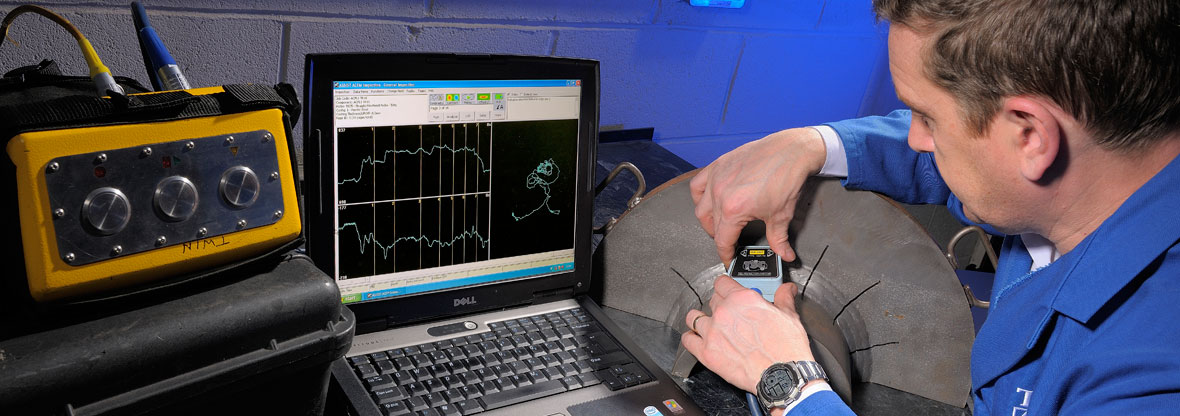

ACFM is a solution that we offer to ensure the quality and safety of welded structures, including those in underwater conditions. Our inspection process starts with cleaning the surface of the weld and applying the probe to the surface to measure the magnetic field produced by the alternating current passing through it. Any changes in the magnetic field caused by defects in the weld will be detected and analyzed by the inspection system.With its ability to test welds in underwater conditions, ACFM is a versatile and essential tool for welding inspection. Our team will provide a detailed report of the findings, recommendations, and any necessary repairs or rework to keep your welding structures in top condition.